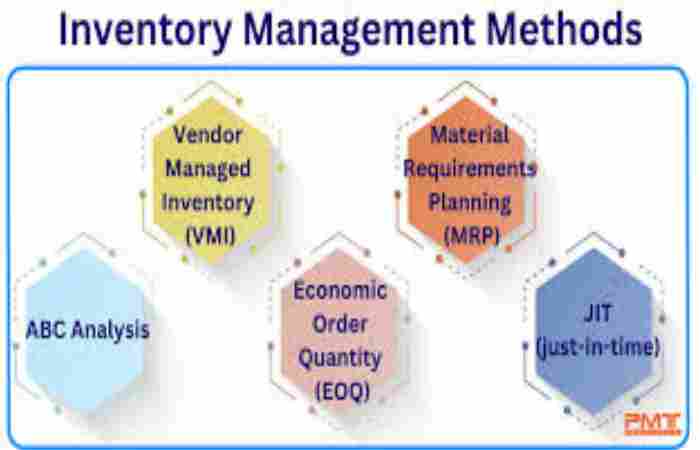

5 Great Inventory Control Methods & Management Techniques

If you run a business that sells products — whether online or offline — you already know how important inventory control is. Managing stock efficiently means fewer lost sales, less overstock, and better cash flow. But with so many tools and techniques out there, it can be hard to know where to start.

That’s why today, I’m breaking down five great inventory control methods and management techniques that can make your operations smoother, faster, and more profitable — no matter your business size.

What Is Inventory Control?

Before diving into the methods, let’s get the basics out of the way.

Inventory control (also called stock control) is the process of managing your products — from ordering and storing to tracking and selling. The goal is simple:

👉 Keep the right quantity of items available at the right time, without overstocking or running out.

A good inventory control system helps you:

-

Avoid stockouts

-

Reduce storage costs

-

Spot slow-moving items early

-

Improve customer satisfaction

-

Forecast demand more accurately

Now that you know why inventory management matters, let’s look at the best methods to make it work for you.

1. Just-In-Time (JIT) Inventory Method

What It Is:

The Just-In-Time (JIT) method focuses on keeping as little inventory on hand as possible. You only order or produce products when they’re needed, rather than keeping large stockpiles.

It’s a lean, cost-effective approach that reduces waste and storage costs — but it requires precise timing and reliable suppliers.

How It Works:

-

Products or raw materials are ordered right before they’re needed for production or sale.

-

Inventory levels remain low, freeing up cash flow.

-

Businesses rely on accurate forecasts and consistent supplier performance.

Example:

Car manufacturers like Toyota use JIT to minimize stock. Components arrive exactly when needed on the assembly line — not weeks in advance.

Pros:

-

Lower storage and carrying costs

-

Reduced waste from obsolete stock

-

More flexibility to respond to market trends

Cons:

-

Risk of stockouts if suppliers delay

-

Requires strong coordination with vendors

-

Not ideal for businesses with unpredictable demand

Best For:

Businesses with stable demand patterns and strong supplier relationships — like manufacturers or tech hardware companies.

2. ABC Analysis (Categorizing Inventory by Value)

What It Is:

ABC Analysis helps you prioritize inventory based on its importance or value. It divides your stock into three categories:

-

A-items: High-value products with low sales frequency

-

B-items: Moderate-value products with medium sales frequency

-

C-items: Low-value products with high sales frequency

How It Works:

-

List all your inventory items.

-

Calculate each item’s annual consumption value (Cost × Quantity sold).

-

Categorize items into A, B, and C groups based on their total value contribution.

Typically:

-

A-items: Top 20% of items = 80% of total value

-

B-items: Next 30% = 15% of value

-

C-items: Remaining 50% = 5% of value

Example:

In an electronics store:

-

“A-items” might be laptops and smartphones.

-

“B-items” could be accessories like headphones.

-

“C-items” are items like cables and phone cases.

Pros:

-

Focuses attention on high-value items

-

Helps prioritize inventory management efforts

-

Reduces excess stock of low-value items

Cons:

-

Doesn’t account for seasonal demand changes

-

May overlook low-cost but high-importance items

Best For:

Retailers, wholesalers, and e-commerce sellers managing a large product mix.

3. First-In, First-Out (FIFO) & Last-In, First-Out (LIFO)

FIFO: First-In, First-Out

This method assumes the oldest stock (first-in) is sold or used first. It’s especially useful for perishable goods like food or medicine.

Example:

A grocery store sells older milk cartons before newer ones to prevent spoilage.

Pros:

-

Minimizes waste and obsolescence

-

Keeps product quality high

-

Reflects the actual product flow

Cons:

-

Can be harder to track manually

-

Doesn’t always reflect rising costs accurately

LIFO: Last-In, First-Out

LIFO assumes that the newest stock (last-in) is sold first. It’s often used in industries where prices fluctuate frequently (like raw materials or construction supplies).

Example:

A steel supplier sells the latest stock first because material costs change month to month.

Pros:

-

Reduces tax liabilities when prices rise

-

Matches current costs to current revenues

Cons:

-

May leave old inventory unsold

-

Not accepted under some international accounting standards

Best For:

-

FIFO: Retailers, grocery stores, and pharmaceuticals

-

LIFO: Manufacturing and industries dealing with cost fluctuations

4. Economic Order Quantity (EOQ)

What It Is:

EOQ (Economic Order Quantity) is a formula-based method that determines the ideal order size to minimize total inventory costs — including ordering and holding costs.

In simpler terms, EOQ helps you figure out how much to order and when, so you don’t waste money on excess stock or frequent orders.

The Formula:

EOQ=2DSHEOQ = \sqrt{\frac{2DS}{H}}

Where:

-

D = Annual demand (units)

-

S = Ordering cost per order

-

H = Holding cost per unit per year

Example:

Let’s say:

-

You sell 12,000 units per year (D)

-

Each order costs ₹1,000 (S)

-

Holding cost is ₹10 per unit (H)

EOQ=2×12,000×1,00010=1,549 units (approx.)EOQ = \sqrt{\frac{2×12,000×1,000}{10}} = 1,549 \text{ units (approx.)}

So, you should order 1,549 units per order for the lowest cost efficiency.

Pros:

-

Balances order and storage costs

-

Reduces stockouts and overordering

-

Improves cash flow planning

Cons:

-

Requires accurate demand data

-

Doesn’t account for bulk discounts or seasonal spikes

Best For:

Businesses with steady demand patterns — like wholesalers, manufacturers, or logistics firms.

5. Perpetual Inventory Management System

What It Is:

The Perpetual Inventory System uses real-time tracking software to update your stock records automatically whenever a sale or purchase happens.

It’s one of the most modern and efficient techniques — especially for businesses managing inventory across multiple locations or online stores.

How It Works:

-

Every sale, return, or purchase updates inventory levels instantly.

-

Systems like Zoho Inventory, QuickBooks Commerce, or TradeGecko integrate with your POS or e-commerce platform.

-

You can track items by SKU, batch, or serial number.

Pros:

-

Real-time inventory visibility

-

Reduces human errors

-

Simplifies reporting and reordering

-

Integrates with accounting and CRM tools

Cons:

-

Can be expensive for small businesses

-

Requires staff training and tech setup

Best For:

E-commerce stores, retail chains, and growing businesses that need accurate, real-time stock insights.

Bonus: Other Inventory Management Techniques Worth Trying

If you’re ready to go beyond the basics, here are a few more advanced methods businesses often use:

1. Dropshipping

Sell products without holding inventory. You forward orders to a supplier who ships directly to customers.

2. Consignment Inventory

Suppliers place stock in your store, but you only pay for what you sell — great for minimizing risk.

3. Safety Stock

Maintain extra inventory as a buffer against unexpected demand or supplier delays.

4. Batch Tracking

Track products by batch or lot to manage expiration dates or recalls (common in food and pharmaceuticals).

Tips to Improve Your Inventory Management Process

Even the best method won’t work without the right mindset and tools. Here’s how to make your inventory management more effective:

-

Use Inventory Management Software: Automate tracking and reports.

-

Regularly Audit Stock: Conduct physical checks to match records with reality.

-

Forecast Demand Accurately: Use sales history and seasonal trends.

-

Set Reorder Points: Automate restocking before items run out.

-

Train Your Team: Ensure staff understands the process to prevent errors.

How to Choose the Right Inventory Control Method

Not every business needs the same system. The right method depends on factors like:

-

Business size

-

Product type

-

Sales volume

-

Supply chain reliability

-

Budget for tools or software

Quick Guide:

| Business Type | Best Inventory Method |

|---|---|

| Small retail store | FIFO or ABC Analysis |

| Manufacturing company | JIT or EOQ |

| E-commerce business | Perpetual System |

| Food & beverage | FIFO |

| Wholesaler/distributor | EOQ or ABC Analysis |

Final Thoughts: Mastering Inventory Control for Long-Term Growth

Good inventory control isn’t just about counting boxes — it’s about understanding your business rhythm.

Whether you use Just-In-Time, ABC Analysis, or a Perpetual Inventory System, the goal is always the same:

Keep your shelves stocked smartly, not excessively.

When done right, effective inventory management:

-

Improves cash flow

-

Boosts customer satisfaction

-

Reduces waste

-

Increases profit margins

So start small — pick one method, track your results, and refine over time.

That’s how successful businesses stay ahead with great inventory control methods and management techniques that actually work.